SANTA CLARA — At COMPUTEX, NVIDIA unveiled a groundbreaking partnership with major Taiwanese electronics manufacturers, propelling industrial digitalization to unprecedented heights. Leveraging NVIDIA’s cutting-edge technology, companies like Delta Electronics, Foxconn, Pegatron, and Wistron are spearheading the adoption of AI and digital twin solutions to transform their factories into autonomous, highly-efficient facilities. By integrating NVIDIA Metropolis vision AI, Omniverse physically based rendering and simulation, and Isaac AI robot development, these manufacturers are revolutionizing their operations, optimizing processes, and driving significant cost savings.

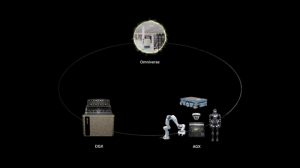

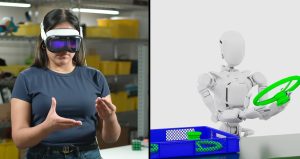

At the forefront of this technological revolution is Foxconn, one of the world’s largest electronics manufacturers. Demonstrated in a keynote by NVIDIA CEO Jensen Huang, Foxconn showcased its use of NVIDIA Omniverse to develop digital twins of its factories, optimizing equipment layout and enhancing worker safety with AI cameras powered by NVIDIA Metropolis. The integration of Omniverse enables Foxconn to create virtual training environments for its autonomous mobile robots (AMRs) and AI robot manipulation arms, accelerating innovation and streamlining workflows.

Similarly, Delta Electronics is leveraging NVIDIA Isaac Sim to integrate its demo production lines, generating synthetic data for training computer vision models. This enables Delta to enhance its automatic optical inspection and defect detection solutions, driving operational excellence and quality assurance.

Meanwhile, Pegatron is deploying NVIDIA Metropolis multi-camera workflows to enhance worker safety and productivity across its extensive factory network. By integrating Omniverse and Metropolis, Pegatron is ushering in a new era of real-time communication between factory operators, optimizing workflows and driving efficiency.

Wistron, a global leader in electronics manufacturing, has embraced NVIDIA Omniverse to accelerate the production of NVIDIA DGX and HGX servers. By building digital twins of its factories and data centers, Wistron has slashed production time and increased worker efficiency by over 50%, setting a new standard for manufacturing excellence.

The expansion of this ecosystem to include leading systems integrator Kenmec underscores the growing adoption of AI and digital twin technologies across the industry. As these technologies become increasingly accessible through reference architecture series, the future of manufacturing is poised for unprecedented innovation and efficiency.

As NVIDIA continues to pioneer advancements in AI and industrial digitalization, the possibilities for revolutionizing manufacturing are limitless. With a comprehensive suite of solutions and a commitment to driving technological innovation, NVIDIA is empowering manufacturers to unlock new levels of efficiency, productivity, and safety in their operations.