STUTTGART — Robert Bosch GmbH, a leading German multinational engineering and technology company, is pioneering the use of generative AI within its manufacturing processes, significantly reducing the time required to plan, launch, and scale AI applications. In innovative pilot projects at Bosch’s plants in Germany, generative AI is being utilized to create synthetic images that enhance the development and optimization of AI solutions for optical inspection, according to a press release published on EuropaWire.

Stefan Hartung, Chairman of the Board of Management of Robert Bosch GmbH, highlighted the transformative potential of this technology, stating, “With generative AI, we’re not only improving existing AI solutions but also laying the foundations for the optimum take-up of this future technology in our global manufacturing network. AI has excellent potential for innovation and can make human work even more productive.”

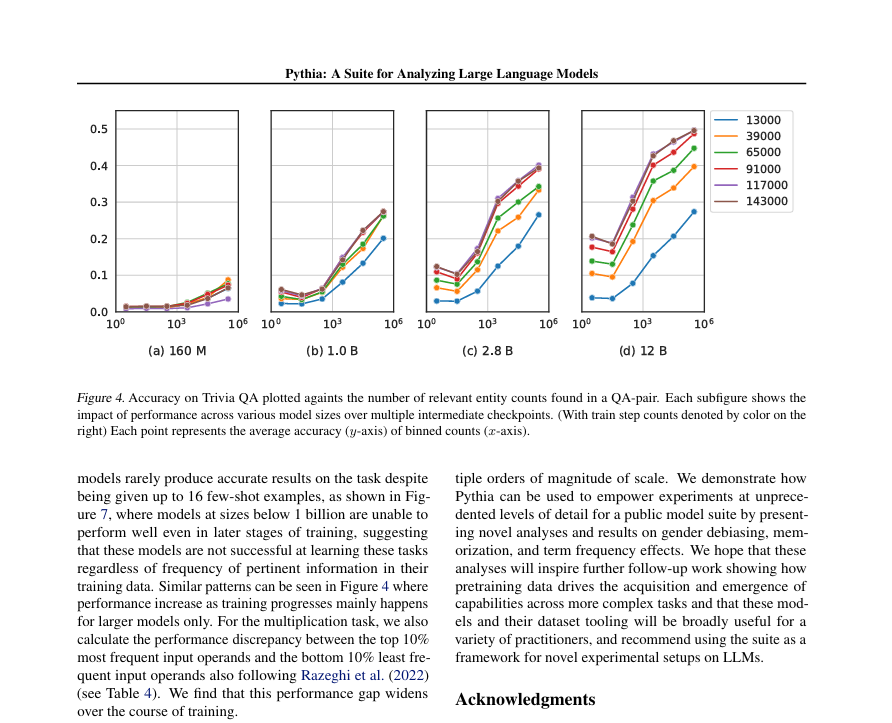

Bosch’s adoption of AI technologies has already yielded significant enhancements in production efficiency. At the Hildesheim plant, AI-based data analysis has reduced cycle times by 15% during the production ramp-up of new lines. Similarly, in Stuttgart-Feuerbach, new AI algorithms have cut component-testing times from three and a half minutes to just three minutes, exemplifying the impactful efficiency gains achievable through advanced AI applications.

Tanja Rueckert, Member of the Bosch Board of Management and Chief Digital Officer, emphasized the dual benefits of generative AI, saying, “Generative AI helps to harmonize individualization and scaling – the technology gives us the best of both worlds.” She underscored the role of AI in advancing modern manufacturing to new levels of efficiency and productivity.

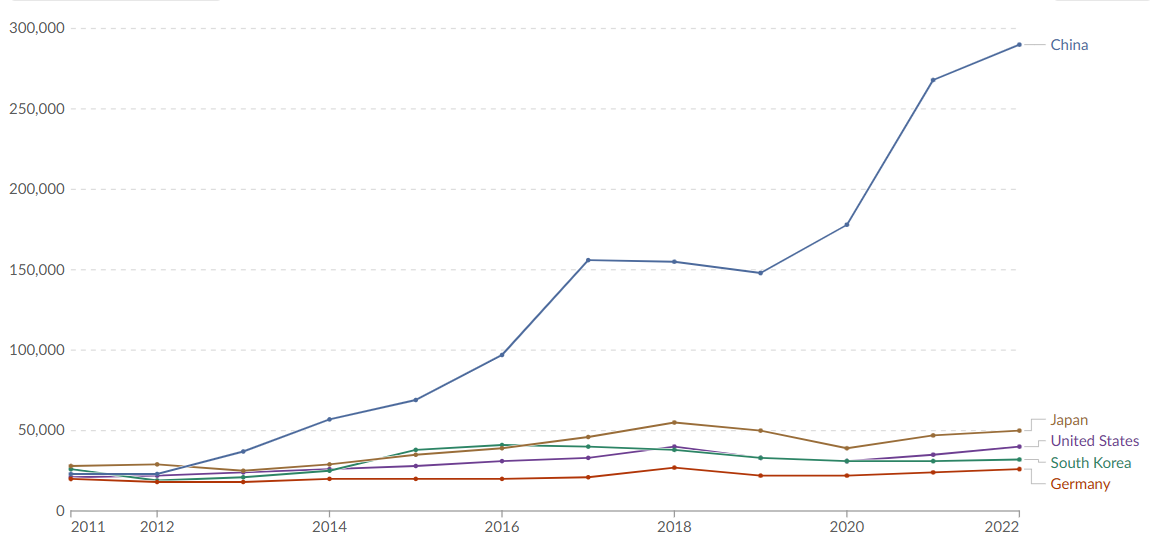

Bosch’s commitment to integrating AI in manufacturing has been recognized globally, with the World Economic Forum designating several Bosch plants as Industry 4.0 “lighthouses.” Notably, the Bursa plant in Turkey has achieved substantial improvements in manufacturing quality through AI, with reductions in water and energy consumption and increases in plant efficiency.

As these pilot projects prove successful, Bosch plans to extend the service of generating synthetic data across all its locations, aiming to lead in the development and application of industrial AI. This initiative is part of Bosch’s broader strategy to merge digitalization with artificial intelligence, driving innovation, efficiency, and sustainability in manufacturing across its global network.